Power Brake Kit | Chrome Booster, Black Wilwood Master | 67-77 Ford Bronco SKU: 3085

Power Brake Kit | Chrome Booster, Black Wilwood Master | 67-77 Ford Bronco

Product Overview:

If you’re tired of fighting your Bronco to a stop, it’s time for a serious upgrade. This Early Bronco Power Brake Kit features a stunning chrome dual diaphragm booster and a lightweight, high-performance black Wilwood tandem master cylinder—all mounted on a custom black powder-coated bracket that bolts directly to your firewall. No inner fender modifications needed. This kit not only delivers modern braking power, but adds a bold visual statement under the hood. Brake lines are sold separately to allow flexibility for custom setups like line locks, proportioning valves, or disc conversions.

Full description

If you’re tired of fighting your Bronco to a stop, it’s time for a serious upgrade. This Early Bronco Power Brake Kit features a stunning chrome dual diaphragm booster and a lightweight, high-performance black Wilwood tandem master cylinder—all mounted on a custom black powder-coated bracket that bolts directly to your firewall. No inner fender modifications needed. This kit not only delivers modern braking power, but adds a bold visual statement under the hood. Brake lines are sold separately to allow flexibility for custom setups like line locks, proportioning valves, or disc conversions.

Early Bronco Power Brake Kit | Chrome Booster & Black Wilwood Master

Put an end to your white-knuckle stops and upgrade your 1966–1977 Ford Bronco with this power brake kit featuring a chrome booster and black Wilwood master cylinder. Designed to bolt directly to your firewall without modifying the inner fender, this all-in-one system combines modern braking performance with show-quality underhood aesthetics. The kit includes a large dual diaphragm booster for enhanced stopping power, mounted via a custom black powder-coated bracket that supports both the booster and the lightweight Wilwood tandem master cylinder. It’s a performance upgrade that delivers both form and function.

-

No Inner Fender Mods Required: Bolt-on installation with no cutting or modifications to factory sheet metal.

-

Large Dual Diaphragm Booster: Provides strong and responsive braking assist, even with larger tires.

-

Lightweight Wilwood Master Cylinder: High-pressure aluminum tandem design, weighing just 3 lbs—75% lighter than cast iron OE types.

-

Custom Black Powder-Coated Bracket: Supports the booster and master cylinder, mounted directly to the firewall.

-

Sleek Performance Look: Chrome booster and black Wilwood cylinder offer standout visual appeal under the hood.

-

Flexible Brake Line Options: Lines sold separately to accommodate custom setups like line locks or proportioning valves.

Get the braking confidence your Bronco needs - this bolt-on kit with chrome booster and Wilwood master offers strong stopping power and high performance style.

Additional Info Detailed Vehicle Fitment

Year

Make

Model

1966*

Ford

Bronco

1967

Ford

Bronco

1968

Ford

Bronco

1969

Ford

Bronco

1970

Ford

Bronco

1971

Ford

Bronco

1972

Ford

Bronco

1973

Ford

Bronco

1974

Ford

Bronco

1975

Ford

Bronco

1976

Ford

Bronco

1977

Ford

Bronco

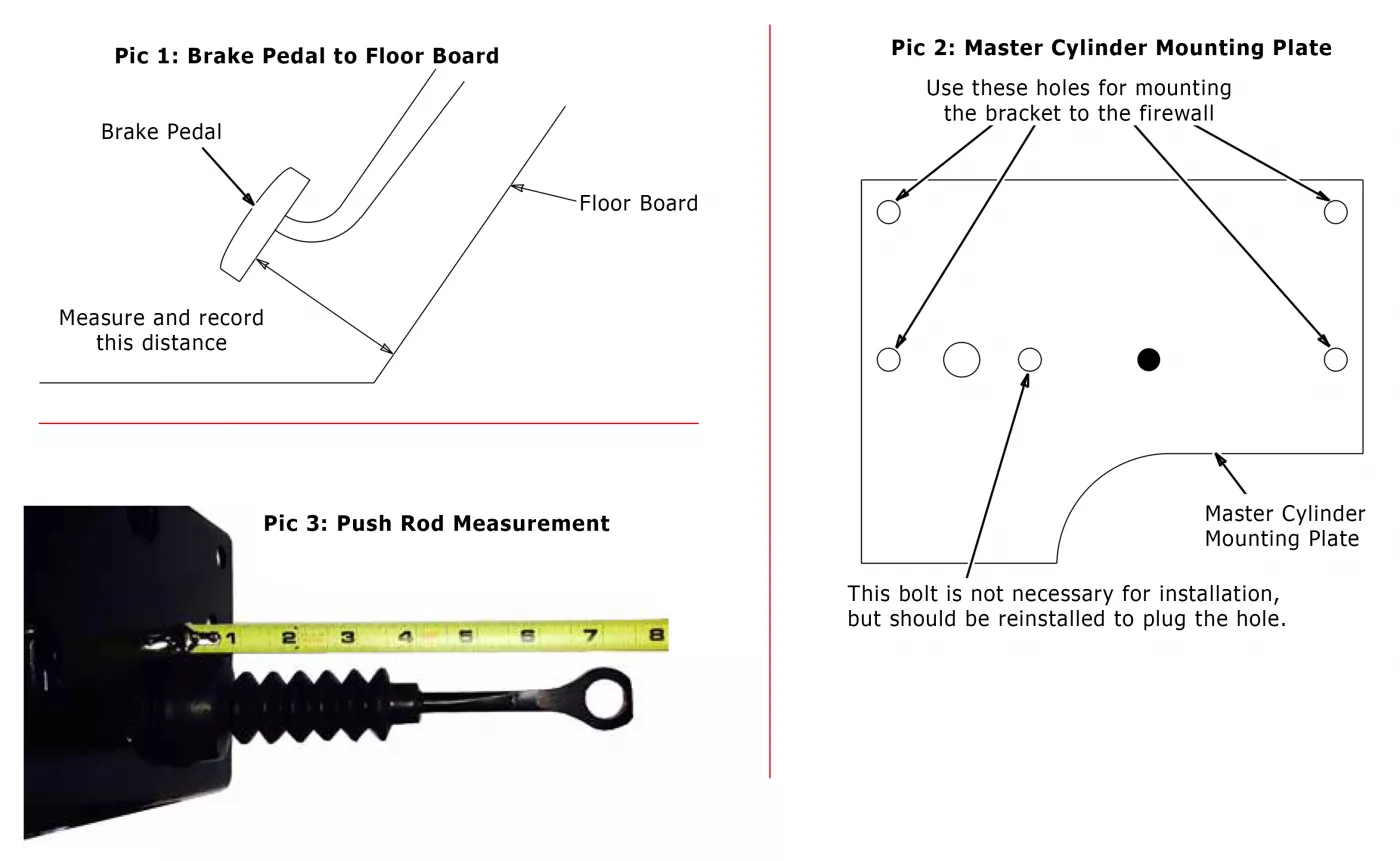

*WARNING* Proper operation of your brakes is essential for your safety and the safety of others. All brake service should be performed ONLY by technicians experienced in the installation and proper operation of brake systems. It is the responsibility of the technician installing any brake component or kit to determine the suitability of the component or kit for the particular application. After installation and before operating your vehicle, always test the brakes function under controlled conditions. DO NOT DRIVE WITH UNTESTED BRAKES! WILD HORSES 4x4 | 1045 S Cherokee Ln, Lodi, CA 95240 | (209) 400-7200 Parts: #3050, #3071, #3085 | Rev 2.0 (1/15/2026) Early Bronco Power Brake Conversion Installation Instructions

Early Bronco Vacuum Power Brake Kit Installation

Before You Start

Installation Steps

Shop Notes

Support